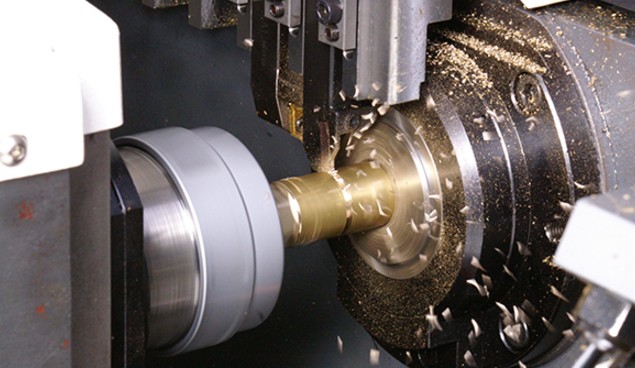

CNC machining masters often encounter abnormal accuracy of workpiece processing in their work, but they don't know where the problem is, which not only causes unnecessary losses, but also greatly affects the follow-up work processing and increases the time cost. In the face of such confusion, the following is to analyze the causes of abnormal machining accuracy.

1、 Causes of abnormal machining accuracy

The causes of abnormal machining accuracy are often hidden and difficult to diagnose, which are usually caused by the following five main reasons: abnormal zero offset of each axis of the machine tool; the feed unit of the machine tool is changed or changed; abnormal operation of the motor, that is, abnormal electrical and control parts; abnormal axial reverse clearance; mechanical defects, such as lead screw and bearing , coupling, etc. In addition, tool selection, programming and human factors may also lead to abnormal machining accuracy.

2、 Fault diagnosis criteria for CNC machine tools

1. External before internal

Numerical control machine tool is a set of mechanical, hydraulic, electrical as one of the machine tools, so the attack of its problems will also be summarized and reflected by the three. Repair personnel should check one by one from the outside to the inside, try to avoid unsealing and disassembling at will, otherwise it will expand the fault, cause the machine tool to lose precision and function.

2. Mechanical before electrical

Generally speaking, mechanical faults are easy to find, while the diagnosis of CNC system faults is more difficult. Before troubleshooting, first of all, check the mechanical faults in advance, which can often achieve twice the result with half the effort.

3. Static before dynamic

The machine tool can be powered on only after it is confirmed as a non-destructive fault through understanding, investigation, test and analysis under the condition of power failure; dynamic investigation, inspection and test can be carried out under the operation condition to find the fault. For destructive problems, we must first eliminate the risk before we can power the machine.

4. Simple before messy

When there are many kinds of problems, which can not be solved at the moment, we should deal with the simple problems first, and then deal with the more difficult problems. After dealing with simple problems, difficult problems are easily solved.

3、 Diagnosis method of CNC machine tool fault

1. Intuitionistic method: (looking, hearing, inquiring) asking about the fault phenomenon and processing condition of the machine tool; looking at the CRT alarm information, alarm indicator, capacitor and other components deformation, smoke and scorch, protector tripping, etc.; listening to abnormal movements; smelling the scorched smell and other peculiar smell of electrical components; touching oscillation, heating, poor contact, etc.

2. Parameter viewing method: parameters are usually stored in RAM, sometimes the battery voltage is insufficient, the system is not powered for a long time or external interference will make the parameters lost or disordered, so the relevant parameters should be checked and corrected according to the fault characteristics.

3. Isolation method: some problems are difficult to distinguish between the numerical control part and the servo system or mechanical part. Isolation method is often used.

4. For the same kind of exchange method, replace the suspected defective template with the spare board of the same function, or exchange the template or unit with the same function.

5. Function program test method: write some small programs with all the instructions of G, m, s, t and function, and run these programs when the fault is diagnosed, so as to judge the lack of function.