The NC machining process analysis of parts is the most important link in the preparation of NC program. From the drawing design to the qualified delivery of finished products, we should not only consider the preparation of NC program, but also consider the influence of various problems in the processing. So before programming, we must analyze the design drawings and technical requirements in detail, so as to obtain the best processing scheme.

1.The original data needed for the formulation of NC machining process route

1. Parts design drawings, technical data, and product assembly drawings.

2. Production batch of parts.

3. Relevant technical standards, such as enterprise standards and process documents, required for parts NC machining.

4. Quality standard of product acceptance.

5. Existing production conditions and data. Manufacturing capacity of process equipment and special equipment, specifications and performance of processing equipment and process equipment, and technical level of workers.

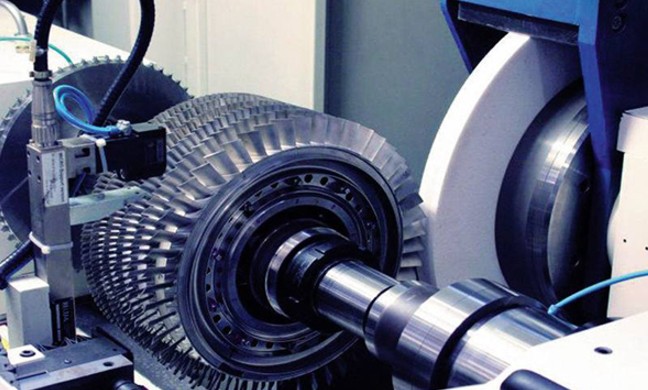

2.Analysis of blank state

Most part design drawings only define the shape and size of the part during processing, but do not specify the data of the original blank material, including the type, specification, shape, heat treatment status and hardness of the blank. When programming, it is an important start to have a deep understanding of the raw materials. Using these original information is conducive to NC program planning.

1. Analysis of assembly drawing and part drawing of products

For the analysis and research of assembly drawing, it is mainly to be familiar with the performance, use and working conditions of the product, make clear the mutual assembly position and function of parts in the product, understand the basis for the formulation of various technical conditions on the part drawing, find out the main technical key problems, and lay the foundation for the formulation of correct processing scheme. Of course, ordinary parts for process analysis, can not carry out the analysis and research of assembly drawing.

2. Process analysis of part drawing

The analysis and research of the part drawing is mainly to review the process of the parts, such as checking whether there are errors and omissions in the view, dimension and technical requirements of the design drawing, especially for the parts with poor structural process, if possible, the designer should communicate with or put forward modification opinions, and the designer should decide whether to make necessary modification and improvement.

(1) Integrity and correctness analysis of part drawing

The view of parts shall meet the requirements of national standards, with accurate position and clear expression; the relationship between geometric elements (points, lines and surfaces) (such as tangency, intersection and parallelism) shall be accurate; and the dimensions shall be complete and clear.

(2) Analysis of technical requirements of parts

The technical requirements of parts mainly include dimensional accuracy, shape accuracy, position accuracy, surface roughness and heat treatment requirements. These technical requirements should be the limit values under the premise of ensuring the service performance of parts. To analyze the technical requirements of parts is mainly to analyze the rationality of these technical requirements and the possibility of realization, focusing on the analysis of the machining accuracy and technical requirements of important surfaces and parts, so as to prepare for the formulation of a reasonable processing scheme. At the same time, through the analysis to determine whether the technical requirements are too strict, because too high precision and too small surface roughness requirements will make the process more complex, processing difficulty increases, and increase the unnecessary cost.

(3) Analysis of dimensioning method

The dimensioning methods of part drawings include local scattered dimensioning, centralized dimensioning and coordinate dimensioning. For the parts processed on CNC machine tools, the dimensions on the part drawing should be marked in a centralized way or with the same datum (i.e. marking coordinate dimensions) on the premise that the performance can be guaranteed. This is not only convenient for NC programming, but also conducive to the unification of design datum, process datum and programming origin.

(4) Part material analysis

On the premise of meeting the function of parts, cheap materials should be selected. When selecting materials, we should base ourselves on China, and do not easily choose expensive and scarce materials.

(5) Analysis on the structure and technology of parts

The structural manufacturability of parts refers to the feasibility and economy of manufacturing the designed parts on the premise of meeting the performance requirements. Good structure technology will make parts easy to process, save cost and materials; poor structure technology will make processing difficult, increase cost, waste materials, and even unable to process. Through the analysis of the structural characteristics, accuracy requirements and complexity of the parts, the processing methods and the types and specifications of CNC machine tools can be determined.